Click the permit number to view: permit1201

The Fort Apache and the lower Corduroy were shot with similar results (structurally similar) to the RCR 01 and the RCR 04. Production or completion efforts will be determined by the viability presented by the production results of the RCR 01 and RCR 04.

Logs:

BLACKSTONE_ROCKING CHAIR RANCH _2 comp

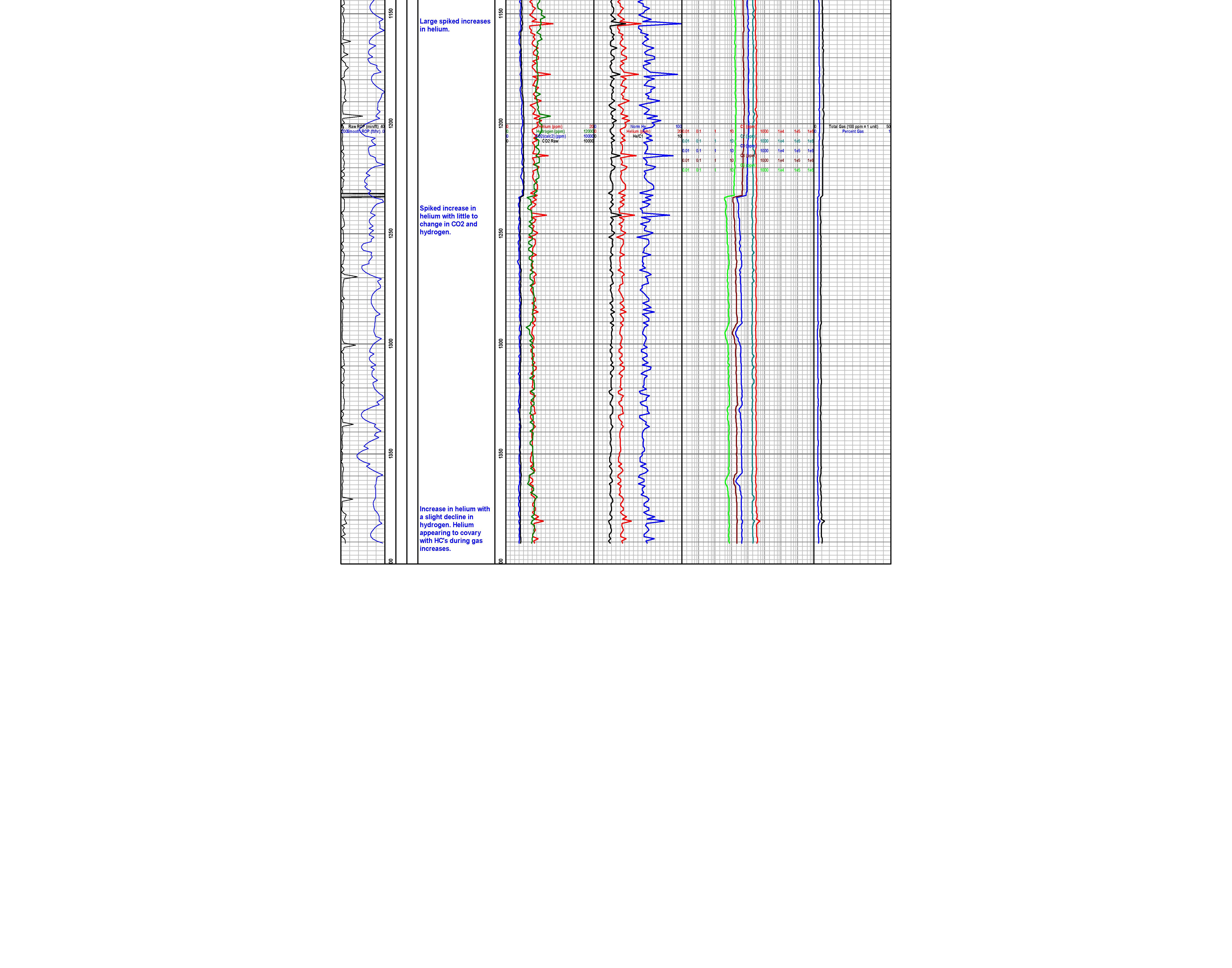

MUD.LOG – # 2 S13-T14N-R19E NAVAJO ARZ BLACKSTONE EXPLORATION ARIZONIA RTD GAMMA

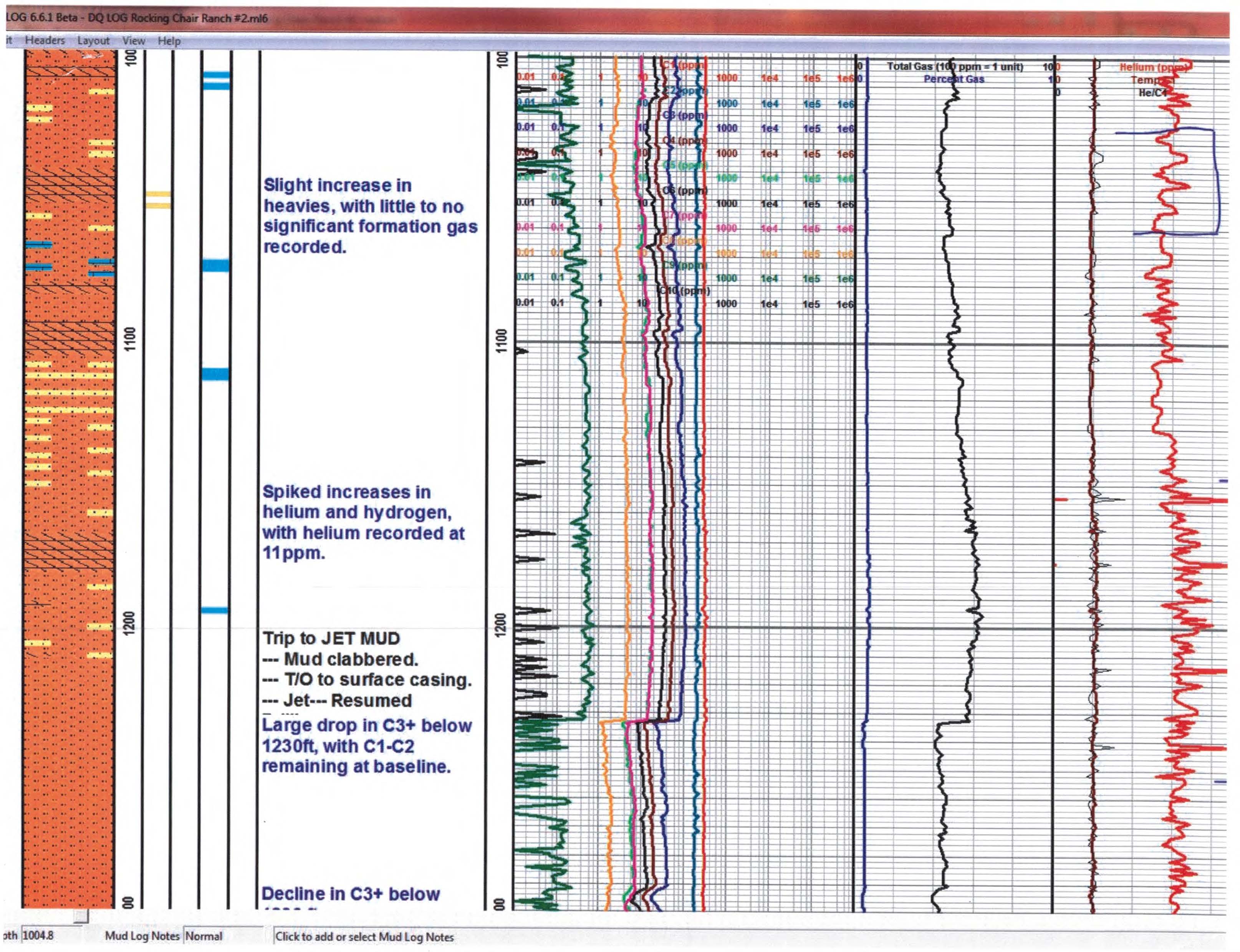

Rocking Chair Ranch #2_Spec. Helium DQ Log_TD

DQ LOG Rocking Chair Ranch #2_TD (1

05-03-2016: Perforating the upper-Supai zones in the RCR02.

1451′-1457′

1438′-1444′

1353′-1363′

1336′-1344′

1175′-1179′

1089′-1095′

04-18-2016: Completion of the RCR02 to commence after completion of the RCR01.

Mud Log: To Download the PDF Click Here: MUD.LOG – Rocking Chair Ranch _2 13-T14N-R19E Navajo Cty, AZ. FINAL (640′ – 1,374′) Blackstone Exploraton Co., LLC.

Final Helium Gas Analysis Log: To Download the PDF Click Here: DQ LOG Rocking Chair Ranch _2_TD (1,374′)

2-16-16

PRELIMINARY GEOLOGICAL REPORT

FOR: BLACKSTONE EXPLORATION

RE: ROCKING CHAIR RANCH #2

(AKA: RCR#2)

1980’ FNL & 1980’ FEL (~SW/NE/4)

SECTION: 13-T14N-R19E

NAVAJO COUNTY, ARIZONA

API# 02-017-20110

ELEVATIONS: KB: 5854’ GL: 5845’

(DRILLING MEASURED FROM KB)

TOTAL DEPTH: RTD: 2689’ LTD: 2684’

CASING RECORD:

16”x53#/ft set @ 42’

8&5/8”x23#/ft set @ 637’

5&1/2”x15.5#/ft set @~2684’

(~1ft off tagged TD: 2685’)

The 22” hole was spudded on November~11, 2015 by Willis Brothers; drilled to 42’ & set 16” conductor casing. The 12&1/4” hole of the RCR#2; also drilled by Willis Brothers to a depth of 640’; with some loss of circulation @ 483’. Willis Brothers rig changed from an air drilling system to a drilling mud system from ~480’ to 640’. 8&5/8” surface casing was set @ 637’; cemented by Basic Energy Services; with a lead cement of: ‘A-Con’ Blend with 3% CaCl, & ¼#/sk Polyflake, 2% WCA1 (12ppg); & a tail cement of: 150 sx of Premium Plus Cement, with 2% CaCl, & ¼#/sk Polyflake. Cement did circulate (~45 bbls). Plug down @ 9:30 am of November~18th; Willis Brothers rig was released.

From November 30th to December 3rd, Blackstone Exploration’s Drilling Rig (Blackstone Exploration Company Tools) moved in and rigged up on the RCR#2. From Dec.4th through Dec.18th: work on rig & prepare to drill the 7&7/8” hole (main hole).

The Blackstone Exploration Rig commenced drilling out under surface (with a 7&7/8” tri-cone bit) @~11:15am on Dec.19th; with some intermittent work on rig/mud pump. On Dec.20th, the drill string became stuck in the hole on a connection at 907’. We spotted ~3000 gal (~71+ bbls) of diesel on bottom, and up across, and above, the annulus between the drill collars and the hole. Also a surface “hammer” was used briefly to free the drill string.

Resumed drilling @~12:03 AM on Dec.22nd. Trip for plugged bit @~920’; & work on pump; drilled to ~939’ @~7:00 AM; 12/22/15.

Drilled to 1374’ @~7:00 AM on 12/23/15; then suspended drilling for holidays.

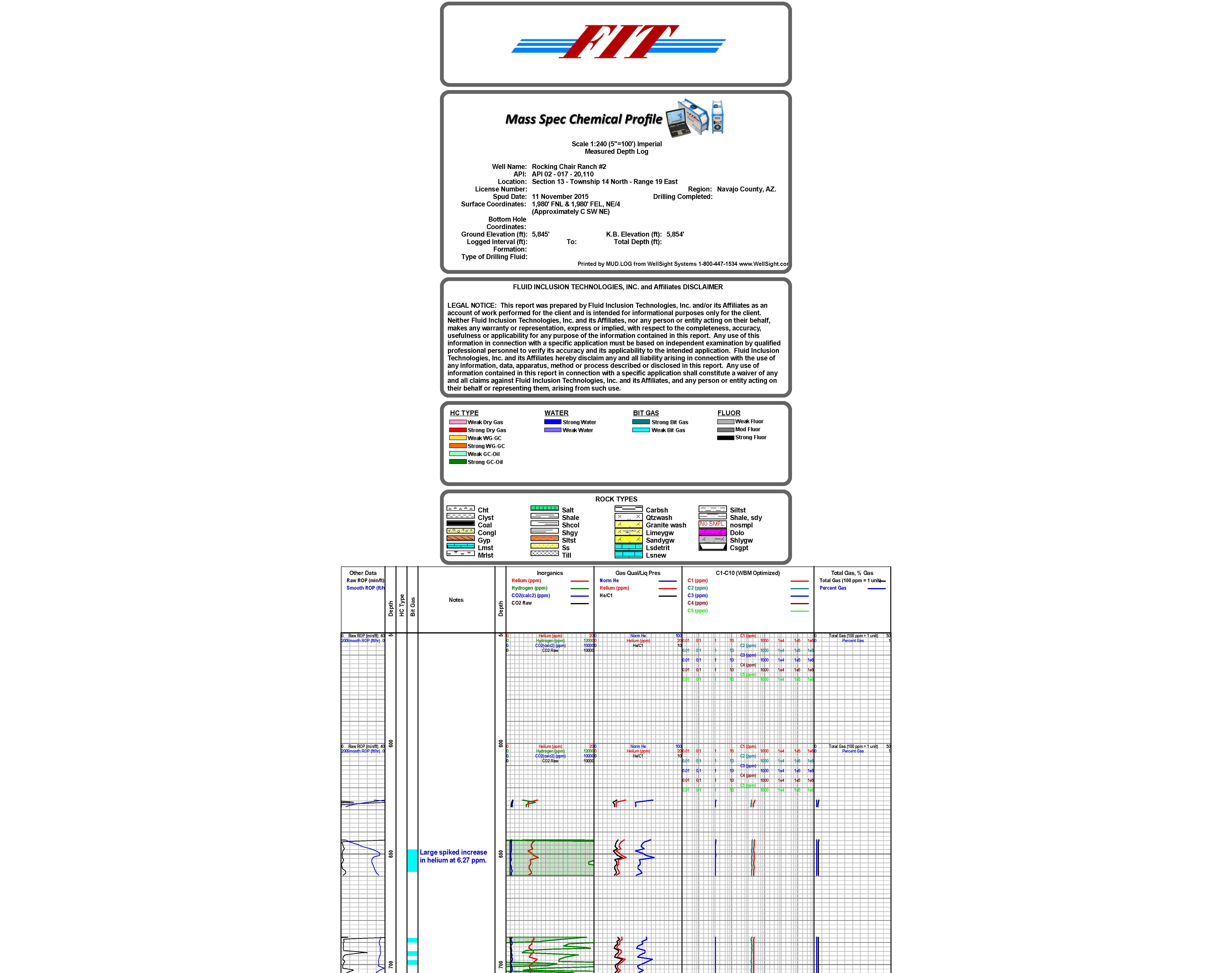

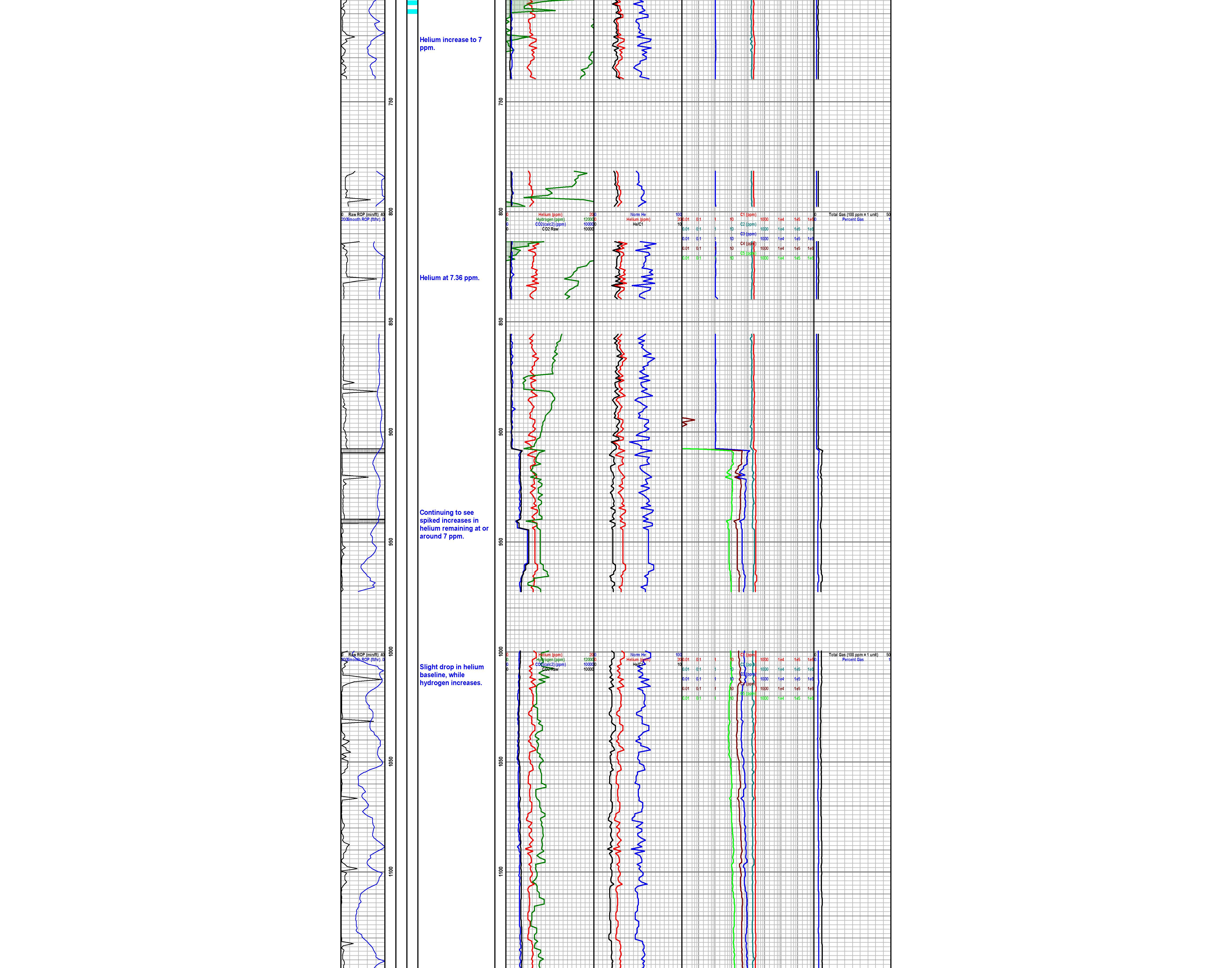

GEOLOGICAL EVALUATION: A Direct Quadrupole Mass Spectrometric Analysis (DQMS) was performed by a Dq1000: a portable mass spectrometer from Fluid Inclusion Technologies, Inc., (FIT) a Schlumberger Company. The “FIT Mass Spec.” was “plumbed” into a conventional hydrocarbon gas detector trailer: from Covey-The Well Watchers; using the TookeDaq hot-wire & chromatograph systems for hydrocarbon gas detection; in conjunction with the “FIT Mass Spec system”- primarily for Helium detection.

The FIT Mass Spec system indicated some anomalous Helium (He) responses; the “background mud gas” was consistently >5 ppm to 7ppm; with some spikes, or “kicks”, of up to 10+ppm, on the He curve, through this upper interval of the Supai Formation, to the Temporary Total Depth (TTD) of 1374’. These anomalous Helium readings are significant, not only to me, but to the Rock Analysis Specialist at FIT; that I conferred with after all of the FIT data was processed.

The TookeDaq “Hot-wire” & chromatograph system did not indicate any significant hydrocarbon anomalies, &/or “gas kicks” from the upper interval of the Supai Formation from ~650’ to the TTD of 1374’*.

Rotary drilling rock samples were caught at “Kelly down” intervals, examined and described by both Geologists on location; the only exception being the final sample taken after circulating at 1374’. That sample was caught after the Covey Gas Detector system was shut down, and rigging down; therefore it was only described by me. The circulating sample at 1374’ was predominately Dolomite (Dolo) and Dolomitic Limestone (DLS); which was a very abrupt change, as compared the previous samples in this interval of the hole. The Dolomite and Dolomitic Limestone had some good to excellent visible porosity, with an obvious show of gas bubbles, associated with a show filmy condensate (visible on top of the water of the rewashed wet sample) after crushing some of the porous cuttings in the 1374’ circulating sample. This sample lagged back to an interval from ~1343’ to 1374’. *I have some concern as to whether or not the gas detector system was shut down a little too early; in order for it to record a lagged gas increase at the very bottom interval of the hole near, or at, the TTD of 1374’.

The majority of the samples, above the previously described interval, were predominately Permian “red beds”; Siltstones (Silts) and Shales (SH), and some Sandstones (SS); with some interbedded Anhydrite (Anhy) and Gypsum (Gyp). The Permian; Supai: Sandstones, and some of the Sandy Siltstones are potential reservoir for a natural gas that is likely to contain some percentage of Helium; especially if the Sandstones &/or Sandy Siltstones are overlain by massive beds of Anhydrite &/or Gypsum. The massive beds of Anhy/Gyp are potentially a vertical permeability barrier (or “cap rocks”) for a reservoir containing a natural gas with a very light constituent; such as the element Helium.

The FIT mass spectrometer, and the Covey gas detector, systems were released during the shut down for holidays.

On January 6th, 2016, drilling operations were recommenced from 1374’.

An MBC Well Logging unit was used, with an I-Ball – Bloodhound infrared unit, along with a conventional analog detector, with Austin Garner as the Mud Logger, from 1374’ to a Rotary Total Depth (RTD) of 2689’.

The rotary drilling rock samples were caught at Kelly down and 20’ intervals from 1374’ to 2230’; then ~10’ samples to RTD; with a bottom hole sample and 20/40/60/80 minute circulating samples at the RTD of 2689’.

The rotary samples from 1374’ to ~1460’ were predominantly Permian “red bed” type Siltstones: rarely sandy with some porosity; <5% to ~10% of Gyp/ Anhydrite; with trace amounts of Dolomite & dolomitic Limestone: as above, and argillaceous dense dolomite and dolomitic Limestone with poor to fair porosity with No Show of Free Oil (NSFO).

From ~1460’ to ~1506’ (lagged) the samples were predominantly Anhydrite and some apparently interbedded Limestone, and dolomitic Limestone, and Dolomite with poor to fair visible porosity with No Show Free Oil (NSFO).

The top of Fort Apache Member of the Supai Formation by rotary drilling rig measurements was at ~1506’(+4348’) [E-log measurements: 1503’(+4351)]

The samples from ~1506’ to 1563’ (lagged to rotary measurements) were predominately dolomitic Limestone, and Dolomite with some fair to good porosity with NSFO, but a trace of residual cut from apparent hydrocarbon stain (still diesel in the mud system); and abundant Limestone with predominately poor to very poor visible porosity, and very rare fair to good visible porosity; with a trace of residual cut from apparent hydrocarbon stain; NSFO.

From ~1563’ to ~1622’ (lagged to rotary meas.) the samples were predominately Siltstone & SH: red beds with very poor to no visible porosity; and from ~1622’ to~1635’ predominately Anhydrite, and some Limestone with very poor to no visible porosity. The samples lagged back to ~1635’ to ~1820’ were predominately red bed Siltstones & Shales with rare Anhydrite and dense Limestone; & rare dolomitic Limestone & Dolomite with trace of fair to good porosity.

From ~1820’ to ~1845’ there was a decrease in red bed Siltstones & Shales; & rare Anhydrite; very abundant Dolomite and dolomitic Limestone, with rare fair to good visible porosity, NSFO.

The samples from ~1845’ to ~1880’ were predominately red beds: calcareous Siltstones & Shales with rare Silty Sandstones with some fair visible porosity, NSFO; and a slight increase in Anhydrite.

From ~1880’ to ~2080’ the samples were predominately calcareous Siltstones and Shales (red beds); with some interbedded Anhydrites, with no apparent significant reservoirs in this interval.

In the samples from ~2080’ to ~2200’, there was abundant silty calcareous Sandstones, with poor to fair visible or apparent porosity, NSFO; with some red bed Siltstones and Shales.

From ~2200’ to ~2660’ (lagged) the samples were predominately calcareous red beds; Siltstones and Shales; with some interbedded argillaceous and dense Limestones with very poor to no visible, or apparent porosity.

[The drill string was again temporarily stuck in the hole, on a connection, at 2218’; again spotted ~3000 gal (~71+ bbls) of diesel on bottom, and up across, and above, the annulus between the drill collars and the hole to free up the drill string.]

There were some Pennsylvanian type dense Limestones, with very poor to no visible porosity; and dark gray, semi-carbonaceous Penn. type Shales in the samples from ~2660’ (lagged) to RTD: 2689’.

Open hole Electric Logs (E-logs) were run at the Rotary Total Depth (RTD) of 2689’; (by C&J, Cased Hole Solutions) consisting of Dual Induction Log, Micro Log & Sonic Log, and Compensated Density / Neutron / PE Log (CNL/CDL/PE). Log Total Depth (LTD): 2684’ (~5’ up hole compared to RTD). There appears to be a ~4 foot measurement difference between E-Logs compared to rotary measurements; after comparison of drilling time curves and tops of zones, etc. (E-Logs ~4’–5’ up hole compared to rotary rig measurements).

Production casing: new 5&1/2” x 15.5#/foot; was set at 2684’ which was one foot off of a tagged total depth of 2685’.

CONCLUSIONS AND RECOMMENDATIONS:

After reprocessing the CNL/CDL/PE Logs; and analysis, with calculations, (using all of the afore mentioned E-Logs) by Richard Leeth, Log Analysist & Engineer; along with an analysis of the E-Logs and calculations, with comparison to the rotary drilling rock samples by me; we have arrived at the following recommendations for zones and/or intervals (within the Supai Formation) to be perforated and tested; E-Log measurements: (zone#1}~1874’–1877’; (zone#2}~1862’–1868’; (zone#3}~1825’–1829’; (zone#4}~1552’–1557’; (zone#5}~1539’–1543’; (zone#6}~1511’–1515’; (zone#7}~1450’–1457’; (zone#8}~1437’–1444’; (zone#9}~1354’–1360’;

(zone#10}~1337’–1343’; (zone#11}~1175’–1179’;

(zone#12}~1089’–1095’.

We are cautiously optimistic that any, to all, of the previously recommended zones could produce a commercial quantity of Helium.

Respectfully submitted,

Roger L Martin, Geologist

1-27-2016 Management has just finished a meeting with the Geological Team of Roger Martin and Dr. Salvatore Mazzullo. They are encouraged by the data and should have their geological reports done shortly, after some log re-processing. They are also picking a Devonian location for the Rocking Chair Ranch, and we will commence drilling the Rocking Chair Ranch #1 shortly after some rig-modification for the challenges of the Holbrook Basin (Please See Wells-Rocking Chair Ranch #1). Our estimated spud date is this weekend. Following is a note from the Helium Engineer with a portion of the FIT Log:

Helium Gas Analysis Log

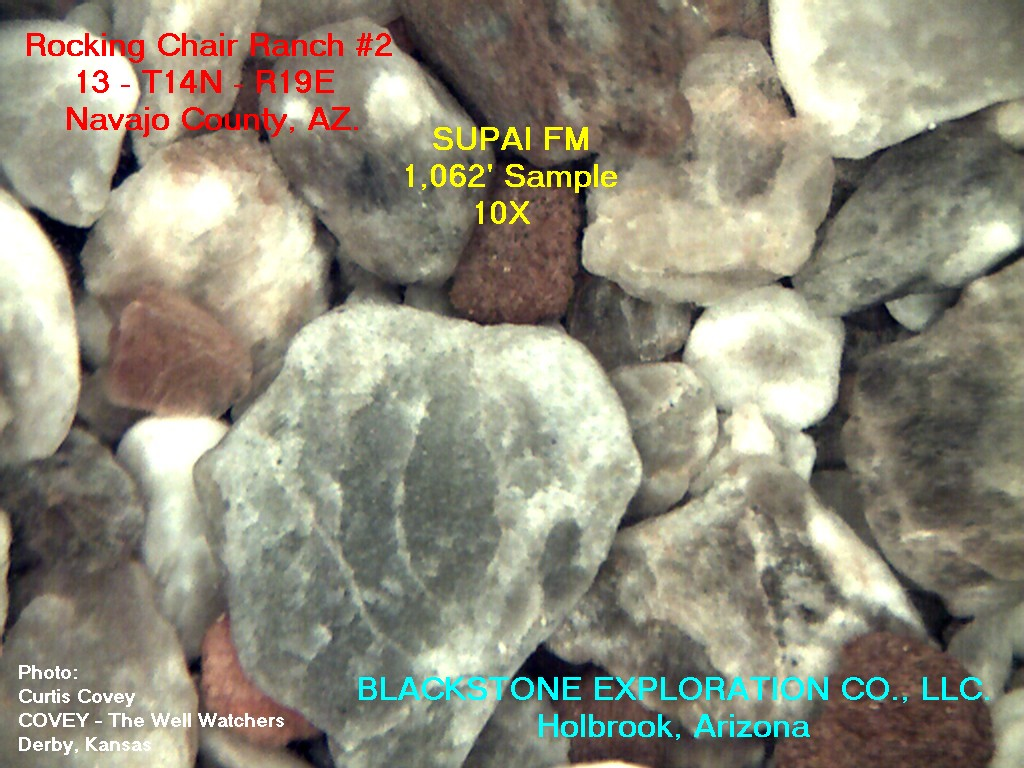

Supai Formation Samples from 1,063′

Blackstone Exploration Company Drilling Rig on the Rocking Chair Ranch #2 at Dusk

Christmas Eve Day 2015

Yesterday Wednesday December 23rd mid morning after going through at least six porous Helium bearing zones at the depth of 1,367 feet we topped the Fort Apache where the samples turned into a grayish dolomite filled with large vugular porosity filled with gas bubbles and condensate which is a heavy gas most likely on top of an oil reservoir underneath it.

We drilled to 1,375′ and are shut down to celebrate the holidays. Our crews are given a week off at which time we will finish drilling to 2,600′. We will then run our open hole quad log and then run in our new 5&1/2″ caseing cementing it in place.

Then we will move on to the RCR 1 which we believe is actually a better drill site than our RCR 2 which we moved on first due to wet conditions and snow.

Merry Christmas everyone!

Carmon Decker Bonanno

Blackstone Exploration Company Incorporated

PO Box 940

156 West Vista Drive

Holbrook, Arizona 86025

PH: 928-524-7786

FX: 928-524-7787

CarmonBonanno@hotmail.com

www.AZOilGas.com